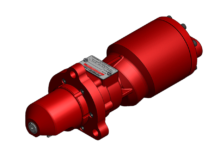

M10 Hydraulic Starter Motor

The M10 hydraulic starter motor is the smallest starter motor in the range. Suitable for engines with up to 3 litres capacity it can produce a maximum torque of 30Nm at 3000 psi (207bar). The M10 is made from cast iron (including the flange and pinion housing) which makes it resistant to rust and corrosion.

The M10 is fitted with a heavy duty inertia bendix and pinion. These are machined from one cast block, eliminating the process of pressing the pinion onto the bendix cup which is a common trait of other starter motors and is a known fail point in many applications.

Non-spark pinions

Depending on your application, the M10 hydraulic starter motor can be fitted with either a steel or beryllium copper pinion. If the environment is potentially hazardous a beryllium copper pinion helps to reduce the risk of sparks.

Key advantages

- Interchangeable design: Both the pinion and mounting flange are interchangeable. This allows the configuration of the starter motor to be altered to suit any application.

- Guaranteed start: Hydraulic energy can be stored indefinitely providing the system is installed and maintained to IPU specifications. Even after discharge, it can be quickly and easily re-charged using a hand pump.

- Performance in all conditions: Hydraulic starters are unaffected by either very hot or cold conditions provided the correct viscosity of oil is used. They similarly operate efficiently following extensive periods of shut down.

- Low maintenance: Hydraulic starting systems are designed to last as long as your engine so why not enjoy low maintenance and replacement costs, as well as peace of mind? All internal components are immersed in oil, protecting it from the adverse environmental conditions that damage electric or vane starters.

Video: 360 degreee view of M10

M10 hydraulic starter motor specifications

| Weight | 9.5 kg (20.9 lbs) |

| Construction | Cast iron (ductile iron) |

| Max. working press. | 21 MPa (3000 psi) |

| Fluid media | Mineral oil |

| Viscosity range | ISO 32 to 46 (SUS 140-230) |

| Temperature range | -30°C to +100°C (-22°F to +212°F) |

| Speed range | 0-4000 rpm |

| Rotation | CW – Standard (CCW – Optional) |

| Duty cycle | Intermittent |

| Overall volumetric efficiency | 95% (minimum) |

| Displacement | 9.98cc (0.6 cu.in.) |

| Max. torque at 21 MPa (3000 psi) |

30 Nm (22 lbf.ft.) |

Dimensions (in mm)

| Overall length | 293mm (11.5″) | |

| Max. motor length | 225mm (8.9″) | |

| Motor diameter | 89.5mm (3.5″) | |

| Dist. between ports | 41.3mm (1.63″) | |

| Inlet port | 3/8″ NPT | |

| Outlet port | 3/8″ NPT | |

| Flange thickness | Depends upon configuration | |

| Pinion hsg. Length | Depends upon configuration | |

| Mounting flange | Depends upon configuration | |

| Flange to ring gear (FRG) | Depends upon configuration | |