Hydraulic Engine Starting Systems

We offer servicing for hydraulic starting systems to help you maintain the safety and reliability of your starting systems.

IPU’s hydraulic engine starting systems are ultra-reliable as they do not depend on electrical power. They offer guaranteed starting for diesel and gas engines up to 80 litres.

This completely independent starting method offers black-start or dead-ship starting capabilities. It is ideal as the primary or secondary method of starting for fire pumps, emergency generators, compressors. Especially for those in hazardous areas that require ATEX safety.

How hydraulic engine starting systems work

Hydraulic starting systems store energy by keeping hydraulic oil pressurised inside a piston accumulator. When the start sequence is activated the oil pressure is released. This is achieved by either a foot , solenoid or manually-operated start valve. Once released, the oil travels to the starter motor, which engages with the engine ring gear and begins to crank the engine.

Once discharged the system can be recharged either manually using a hand pump, or automatically using a hydraulic pump or the host machine’s on-board hydraulics.

Custom hydraulic engine starting systems

Few of the new oil platforms, drilling rigs or mining vehicles have an abundance of free space. Therefore any hydraulic starting system must fit into whatever space is available. That’s where IPU’s expertise and flexibility comes to the fore.

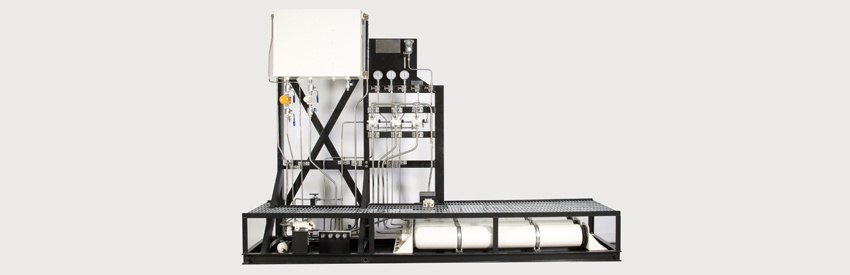

A standard hydraulic starting configuration places the accumulators next to the starter motor and engine. However, this is not always possible. In these situations IPU can design a custom package that places the accumulators wherever there is space.

As an example, BP asked IPU to provide a hydraulic system for an offshore platform in the Caspian sea. Unfortunately, the space available on the platform was limited. The solution was to place the accumulator tanks below floor level (as shown below). This ensured that the starting system took up minimal space and daily operations could continued unobstructed.

IPU’s engineering team will work closely with your designers to ensure the custom starting package integrates perfectly into the proposed platform, rig or vehicle. It will also meet any specialised starting requirements you have: number of start attempts, cycle time, adverse environmental conditions, etc.

ATEX-approved hydraulic engine starting systems

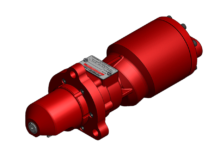

If you or your products operate on an offshore platform or in an underground mine ATEX certification means safety. IPU can supply a starting system that complies with any ATEX requirements. Our ATEX-approved starter motors mitigate the risks through a cast iron outer casing and use a pre-engaged starting mechanism. Our M22 and M28 starter motors are fully compliant with ATEX EN-1834-1 and EN-1834-2.

Hydraulic engine starting systems servicing

IPU offer servicing for hydraulic starting systems to help you maintain the safety and reliability of your starting systems. Our experienced team of service engineers will visit your installation and service your primary or secondary starting systems, regardless of make or manufacturer.