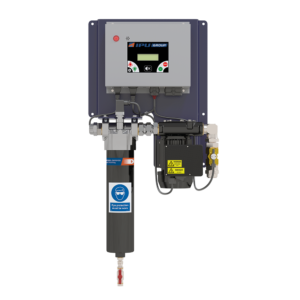

EKO with Kapture Technology Fuel Polishing System

The EKO System with Kapture technology is a high-performance fuel polishing system that represents a major step forward in protecting diesel fuel from harmful contaminants in storage tanks up to 10,000 litres capacity.

The system builds on IPU Group’s extensive expertise in fuel management and brings together a compact high-performance fuel polishing unit with an intelligent microprocessor control module. This specialised combination is custom designed to monitor and control fuel cleaning systems with a lower purchase and lifetime maintenance cost in mind.

But this is achieved without compromising on performance. The EKO System with Kapture Technology delivers an exceptional cleaning capability that is 87% higher than the industry standard, achieving a 13/11/18 level of cleanliness at both high and low flow rates.

IPU’s Kapture Technology

At the heart of the EKO System with Kapture Technology polishing system is a microprocessor-controlled input/output control module, which is installed and connected using simple plug-n-play connections and enables remote configuration and continuous monitoring anytime.

System flexibility is essential when operating in a diverse range of applications and so monitoring is highly adaptable, whether using the programmable seven-day time control function, manual control (fascia control) or expanded further to manage communication remotely via BMS input or RS485. The system can function in either full mode for more regular operation or ‘holiday mode’ when running for limited or occasional periods.

Predictive maintenance

IPU’s Kapture Technology continuously monitors fuel contamination levels and allows the user analyse trends data over time.

Analytical data and trend information can be saved and downloaded from the system allowing a deeper analysis of site conditions which could affect fuel condition or cause degradation.

Total flexibility

The system integrates with almost any sensor (0-5V, 0-10V, 4-20mA, Resistive and Digital), allowing the EKO System with Kapture Technology to be extremely flexible.

All sensor data can be saved in the control panels non-volatile memory, allowing up to two years (depending on frequency and quantity of sensors being saved) of historical data to be captured by the panel for direct viewing on the LCD display or to download via IPU’s own E.A.R.L.™ software via a USB connection.

Specifications

| SYSTEM | |

| Dimensions (H) x (W) x (D) | 930mm x 445mm x 217mm |

| Weight | 31kg |

| Operating Conditions | -20°C to +60°C |

| Environment | Control Box IP44 |

| Connections | 1” BSPP Male Coned Inlet & Outlet |

| FILTRATION | |

| Fluid Compatibility | Diesel & mineral oils |

| Media | Particulate – 1, 3, 5, 10 or 25 Micron & Water |

| Filter Blocked Indicator | Electronic via Control Panel LED |

| ELECTRICAL | |

| Voltage | 230 VAC (±10%) |

| Nominal Frequency | 50Hz |

| Nominal Motor Current | 3.5A |

| Motor Protection | Automatic Thermal Protection Switch |

| PUMP | |

| Flow | 50 litres per minute |

| Type | Self-Priming Vane |

| Duty Cycle | Continuous |

| Noise Level | <85dB @ 1 Metre |